BPMsport S65 Refresher / E46 Build / Forensic Knock Analysis

BPMSport S65 Refresher / E46 Build / Forensic Knock Analysis

Preface:

Being that the E9x M3 is the last Generation of the S65 V8, we wanted to have a “pristine” example of our 12/07 build E90 M3 Sedan. The S65 V8’s are in high demand given that the E9x M3 line is being phased out for the newer inline six turbo motors. This coupled with the ongoing bearing clearance debacles that many of you are familiar with and our desire for an “S65” project prompted the reasons for this build. We all know that there is nothing like a naturally aspirated V8 that rev’s to almost 9K RPM!

S65 Engine Availability:

Checking BMW availability of the S65 engine solidified our decision to go this route. Checking all of the BMW parts distribution warehouses, (Ontario, DMDC LA, Jacksonville, Nazareth) shows something a bit disturbing… Not ONE single S65 appears to be in any of BMW’s United States parts distribution centers. Checking a bit further into the availability system, there were only two S65’s showing available in Germany. Well, now there is only one left as of today (11/18/2013 1:30PM)! In three weeks the S65 engine will be traveling from Germany until it reaches Los Angeles to be installed into our 2008 M3 E90 Sedan. We had thoughts in the past about doing a low compression build, or a supercharger – but at the end of the day we were interested in retaining a pristine example of the high revving naturally aspirated V8 that we have all come to know and love. Not many cars behave with such prediction. (Update: Checked today 11/29, quantity now shows zero.)

So… why go with a new engine instead of rebuilding the current one? A few reasons. The production date of the engine in our E90 M3 was 01/2007, which is one of the first S65’s around. In fact, our E90 M3 has a build date of 12/2007, and is one of the first V8 M3’s to ever hit the United States. Having programmed over a thousand M3’s in over twenty five different countries, most of the build dates are 03/08 or greater, and the earliest build date we’ve ever seen was 11/07. Our M3 has gone through a few oil analysis reports from Blackstone Labs throughout its life, and high levels of lead have been a consistent issue on these reports. This was very concerning and disheartening, especially since every measure to ensure this engine was properly cared for was taken. Oil and filter changes were performed at no more than 6,000 mile intervals. The engine never exceeded 3,000 RPM’s when cold. In fact, we started offering our cold start rev limit reduction feature because we were very concerned that the life of these engines was being reduced by high RPM activity before the infamous TWS oil reached operating viscosity. It’s one thing when you’ve purchased a used car and are not sure if the previous owner exercised caution and care – and another when the car is delivered with two miles on the odometer and you’re fully aware of its complete history. For a car that was meticulously maintained at more than twice the factory intervals, it was certainly a bit frustrating to see elevated levels of lead on every report.

Track Testing:

This engine served us very well and held up under extreme conditions. Back in September 2012, we tested our 240E software on the track in 100F + ambient temperatures with oil temperatures meeting or exceeding 300F on the three cars we brought out – our 2008 E90, a 2012 E92 and a 2012 E93. All of them performed flawlessly. The E90 did have warnings about over temperature but never skipped a beat. This is likely due to the crankshaft pulley slightly under driving the water pump as the other two cars had the stock crankshaft pulley and did not trigger this warning. Given this, the crankshaft pulley will likely be removed and put back to stock to ensure that coolant temperatures are kept in check during more extreme driving events. In our latest software, aside from offering the coldstart rev limit protection when the motor is cold, we have also modified the temperatures at which the vehicle reduces the RPM limit based on oil temperature, coolant temperature, and transmission oil temperature. This ensures that the engine remains safe even with the most brutal of beatings on the track in extreme conditions. This goes above and beyond BMW’s programmed protection levels to ensure the S65 continues to deliver for years to come. In the latest 240E software version, BMW actually allowed the engine oil temperature to rise 5C more than previous versions before a redline restriction was enacted.

Combustion Quality Discussion:

Another important thing to note is the amount of knock/detonation the vehicle sees, especially in extreme conditions and with 91 octane gas. There are a few different forms of combustion quality problems that the MSS60 control unit detects. Combustion misfires are an issue with these engines and can be caused by a number of reasons. Things that can cause combustion misfires are as follows:

Hardware issues, fuel quality, faulty or fouled spark plugs, faulty ignition coils, fuel pump or pressure regulation problems, camshaft or crankshaft sensor problems, idle control valve problems, oxygen sensor problems, etc.. This is not a complete list.

As you can see, quite a number of issues can cause combustion misfires. The MSS60 does not have conventional methods of listening for ‘knock’ – rather, it uses feedback form the coils and plugs to detect combustion quality. The DME recognizes and records two main forms of misfires: ‘standard’ misfires, and misfires with combustion deterioration. The latter is a more severe form and will cause limp mode as such events can damage the catalytic converter and have a more pronounced effect on the engine.

If requested, we can go into an extremely technical discussion on this. This is a VERY sophisticated system and in our opinion, the window for which the system triggers safety mechanisms leaves much to be desired. Why do we say this? Because the misfire detection system has programmed windows in which to trigger faults, issues with combustion that are not frequent within a short time frame are not causing service engine soon lights. One thing that we have religiously seen in almost every S65 motor is that the count of misfires and misfires with combustion deterioration is religiously higher in cylinders #3 and #7. About 8 months ago, our E90 M3 was misfiring on cylinder three and this was tracked down to a faulty coil. However, in more than one situation, we’ve seen extremely high differentials on S65’s we’ve checked in the amount of logged events per cylinder. As an example, before tuning a customer’s vehicle about 3 or 4 months ago, we checked logs from the DME. What we found is that cylinder 7 had over 10,000 misfire events – while the other cylinders had less than 1,000. No check engine light. This is alarming – as the differential here clearly signifies an issue with the plug, coil, Ignition wiring, injector, etc.. Because these events were spread out over such a lengthy period of time, the window was missed for triggering any alarms that there may be a potential issue here.

We have been investigating this, and working on modifying the windows for fault code triggering. We’ve also been testing selective reductions in ignition timing in specific cylinders based on a number of different measurements of combustion quality as read from the plugs and coils.

The Build (E90):

-New S65 (Currently on the way from Germany – pictures will be added on arrival)

-VibraTechnics motor mounts

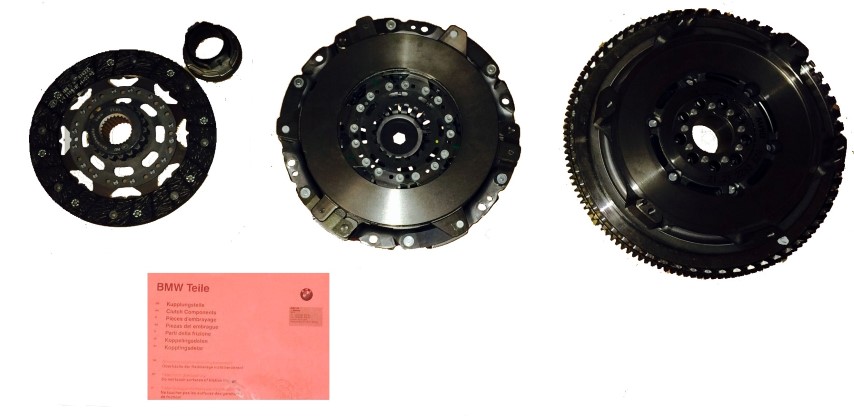

-New Factory Clutch

-New Factory Flywheel

(The new starter and alternator was purchased for two reasons. #1 being that we want the E9x to have all of the freshest components, and #2 because it completes our automatic start/stop retrofit from months ago by upgrading the components to the latest and greatest versions built for these features.

http://www.m3post.com/forums/showthread.php?t=731085

Pictures of the following items will be posted when picked up from the McKenna BMW Parts Dept:

-New Starter

-New Alternator

-New Precat Oxygen Sensors

-8 New Coil Packs

The low pressure fuel sensor, throttle actuators, and idle control value were already replaced in the last 10K miles as they are the most common failure points in the E9x M3.

We also cleaned the Akra TI tips using a brush a denatured alcohol to refresh them. Here are a couple pics before polishing:

We’ve also got a Mode Carbon CF Front spoiler collecting dust for the last six months, so might as well put that on too! It’s really a quality piece.

E46 Build:

Part of the inspiration from this build came from this picture:

Thanks to jphughan for the pic.

It’s still undecided at this point, but since we’ll have a spare S65 motor left over, we’ve been toying with the idea of dropping this into an E46. One of our customers has been setting quite a few records with his BPM Stage II Tuned E92 M3, and it would be exciting to see him tear it up in an E46 Track build powered by an S65 V8 powerplant. A link will be added when the thread on his car is posted.

While in Vegas after SEMA, we spent some time mapping out the wiring and electronics for the build. We wanted the car to have the same type of security that a factory BMW would have. After spending a few hours, we finished up the schematic and wiring for the build. The same key that starts the E90 M3, will also start the S65 Powered E46. This is often one of the biggest hurdles when putting an S65 powerplant in another chassis, and we are happy that this part of the project is ready to be put in motion. For now we are trying to decide whether to start with an E46 M3 shell or a complete car. As far as the motor, we will be checking the clearances and then likely have some work done to the crank/journals, as well as replacing the rod bearings to ensure that it consistently delivers on the track for years to come. We’ll definitely post more pictures of the S65 refresher in the E90, as well as the motor that will be going in the E46 if we continue with this project. For now we’ll leave you with a couple shots pre-engine removal. We also took samples that will be sent out to Blackstone Labs.

The most painful part will be going through the 1,200 mile break in. The tune will be modified to prevent any sort of temptation during that period! We’ll certainly be back with more pictures and information as the build of the E90 reaches completion.